Workflows and Instrumentation for Cryo-Electron Microscopy: An Overview

Frédéric Leroux

Advanced Workflow Specialist Leica Microsystems

Read BioFrédéric Leroux completed his Master degree in Biology in 2007 at the University of Ghent where he gained experience in biological EM sample preparation. In 2008, he moved to the physics department at the University of Antwerp where he obtained his PhD in 2012. At the EMAT research group he specialized in advanced electron microscopy of composite materials and polymers. In 2016, he joined Leica Microsystems as Application Specialist Nanotechnology. He thereby uses his multidisciplinary background and broad microscopy experience to improve EM sample preparation of a variety of materials (polymers, composites, biological and industrial materials).

CloseIn this webinar, you will learn about:

- Optimal vitrification of biological samples.

- Cryo-electron microscopy of vitreous sections (CEMOVIS) of large samples.

- Screening vitrified specimens using cryo-fluorescence microscopy.

- Freeze fracturing and cryo-coating.

- Cryo transfer for high vacuum instruments.

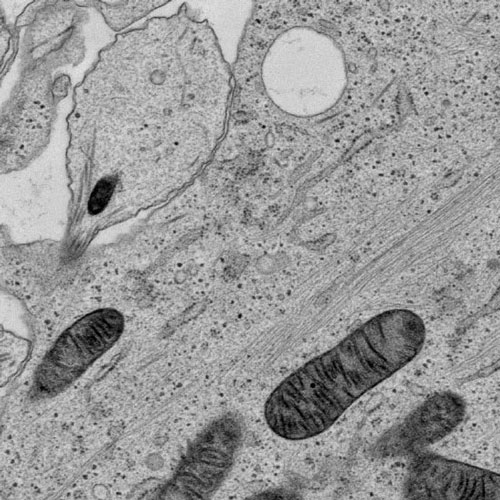

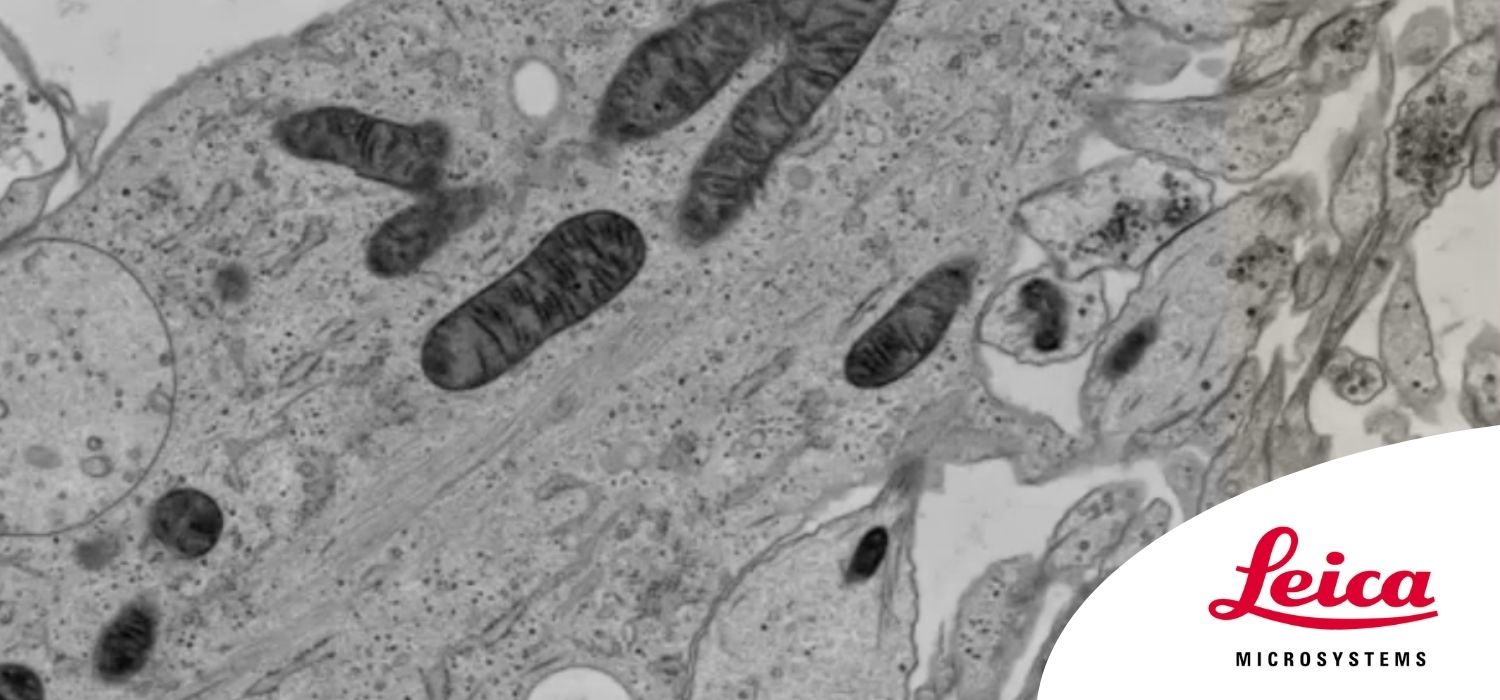

Cryo-electron microscopy is an increasingly popular modality to study the structures of macromolecular complexes and has enabled numerous new insights in cell biology. In recent years, cryo-electron microscopy has expanded further towards in situ structural biology and has become the go-to technique for resolving structures in their native context.

Similarly, freeze-fracturing and cryo-scanning electron microscopy (SEM) have received increased interest. Cryo workflows typically start with vitrification, and all subsequent steps—including screening, processing, transfer, and imaging—are performed under cryogenic conditions.

During this webinar, you will receive a full overview of cryo-preparation instruments, including vitrification, light microscopy screening, sectioning, planing, fracturing, milling, coating, and transfer. All of these steps happen under cryogenic conditions while minimizing contamination and without risk of devitrification. We discuss several cryo-workflows to explain the full potential of the individual instruments.